August 19, 2025

The healthcare distribution sector in Malaysia is undergoing a strategic transformation, driven by the urgent need for efficient, reliable, and technologically advanced solutions. As demand for medicines, medical supplies, and wellness products grows, pharmacy distributors and healthcare logistics providers are embracing innovation to stay competitive. The shift from outdated, manual processes to automated, data-driven systems isn’t just a trend—it’s becoming an essential component of operational success.

Malaysia’s healthcare supply chain is a multifaceted network involving manufacturers, independent pharmacy distributors, wholesalers, and retail pharmacies. Historically, operations relied on phone orders, paper-based records, and fragmented coordination—methods that are no longer sustainable. The rise in chronic diseases, stricter NPRA compliance requirements, and consumer expectations for faster, more transparent services have exposed critical inefficiencies.

✔ Limited supply chain visibility leading to frequent stockouts or costly overstocking

✔ High logistics expenses due to unoptimized delivery routes and redundant processes

✔ Manual documentation errors increasing compliance risks and audit failures

✔ Fragmented supplier-retailer communication causing delays and order inaccuracies

Take, for instance, a Johor Bahru-based pharmacy sourcing OTC drugs from one distributor pharmacy and prescription medicines from another. This disjointed approach results in duplicated efforts, delayed deliveries, and frustrated customers. Similarly, a Kuala Lumpur medical supplier reported a 30% increase in operational costs due to outdated inventory tracking methods.

Regulatory pressures are further accelerating the need for digital transformation. Good Distribution Practice (GDP) guidelines now mandate stringent cold chain monitoring, batch-level traceability, and real-time expiry date tracking—requirements nearly impossible to meet without expert tech integration.

Learn More : Top 10 Pharmaceutical Companies in Malaysia 2024

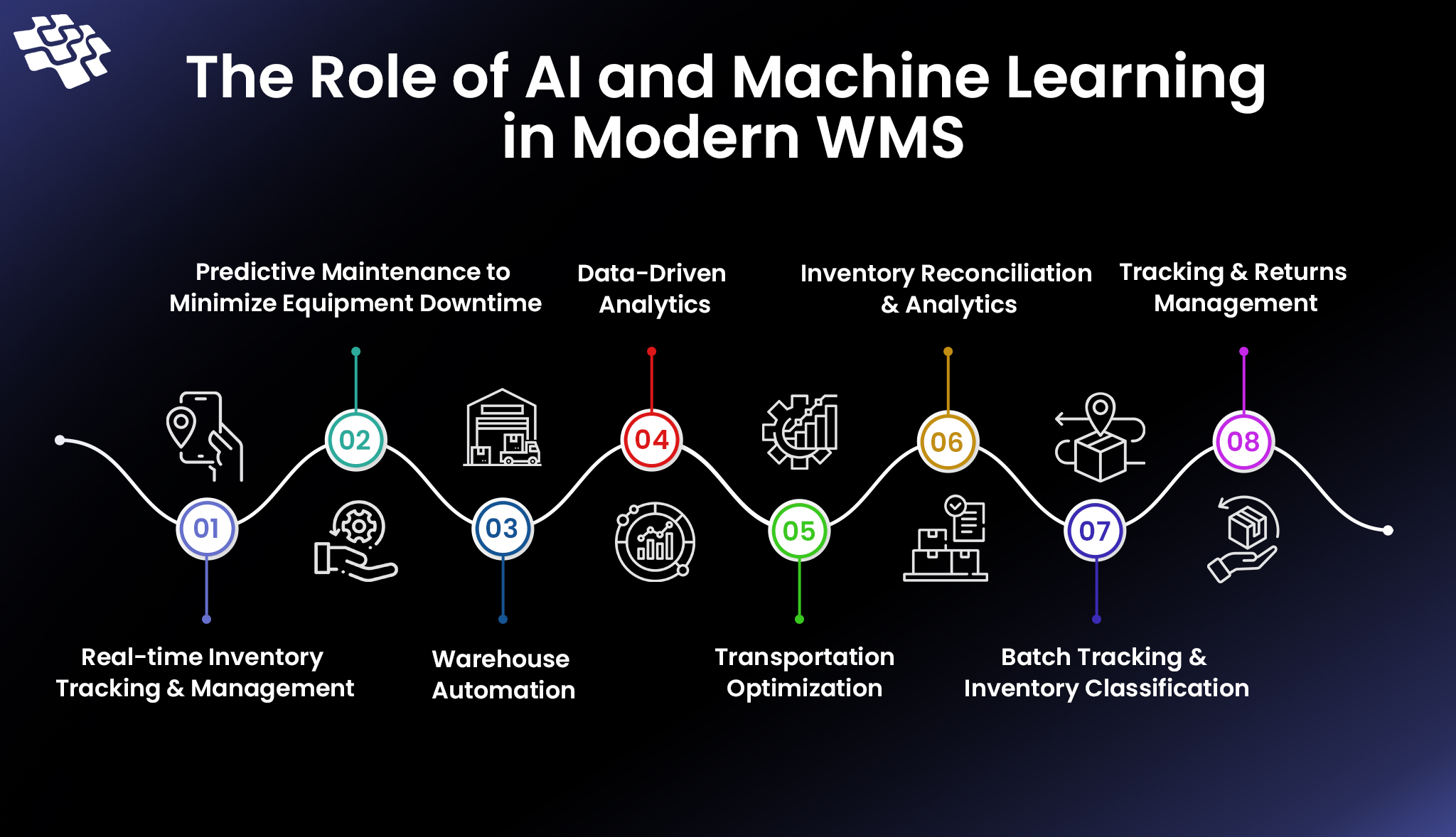

Warehouse automation is no longer a luxury but a proven necessity for pharmacy wholesale distributors aiming to scale efficiently. Modern facilities leverage Automated Storage and Retrieval Systems (ASRS), robotic pickers, and AI-powered conveyor belts to minimize human error and maximize throughput.

A Selangor-based healthcare logistics provider implemented ASRS and saw transformative results:

85% reduction in picking errors, ensuring accurate order fulfilment

40% faster order processing, slashing dispatch times from hours to minutes

Optimized storage capacity, handling 10,000+ SKUs without expanding physical space

Beyond hardware, digital inventory management systems offer real-time insights into stock levels, expiry dates, and batch recalls. These platforms sync seamlessly with distributor pharmacy ordering systems, eliminating manual data entry and reducing discrepancies.

Cold chain compliance is another area where automation shines. Temperature-sensitive products like vaccines and biologics require reliable monitoring. IoT-enabled sensors track conditions 24/7, automatically flagging deviations and generating audit-ready reports—a game-changer for Malaysian pharma distributors navigating NPRA audits.

✔ Cost savings through reduced labor dependency and optimized resource allocation

✔ Enhanced regulatory compliance with automated documentation and reporting

✔ Improved customer satisfaction via faster, error-free deliveries

Learn More : The Role of End-Cap Displays in Increasing Pharmacy Sales in Malaysia

In an industry as dynamic as healthcare, intuition alone isn’t enough. Real-time analytics empower pharmacy wholesale distributors to make strategic, data-backed decisions. Advanced dashboards aggregate data from inventory, sales, and logistics to uncover trends, predict demand, and identify inefficiencies.

A Penang distributor pharmacy adopted an AI-driven analytics tool and achieved:

20% lower fuel costs by optimizing delivery routes based on traffic and demand patterns

15% reduction in expired stock thanks to predictive expiry date alerts

Dynamic pricing adjustments during seasonal demand spikes (e.g., flu season, Ramadan)

✔ Demand forecasting to prevent overstocking or shortages

✔ Supplier performance tracking to negotiate better terms and ensure quality

✔ Route optimization to cut delivery times and fuel expenses

For example, a Klang Valley medical supplier used analytics to identify a recurring 20% surge in vitamin sales during monsoon season—allowing them to adjust procurement in advance and avoid lost sales.

Learn More : Pharmacy Merchandising: Best Practices for Product Pricing and Promotion in Malaysia | How technology improves healthcare supply chain management

Siloed systems are the Achilles’ heel of traditional distribution. Integrated digital platforms unify manufacturers, distributor pharmacies, and retailers on a single interface, streamlining communication and order management.

A trusted Malaysian healthcare logistics provider deployed an integrated platform with:

Custom dashboards for suppliers to monitor stock levels and sales trends

Automated invoicing and order tracking, reducing processing time from 48 hours to under 2 hours

Real-time notifications for out-of-stock items or delayed shipments

✔ End-to-end visibility for manufacturers, distributors, and retailers

✔ Faster order cycles with automated workflows and reduced manual intervention

✔ Improved accuracy in invoicing and inventory reconciliation

Consider a skincare brand in Malacca that uses the platform to track real-time sales data across partner pharmacies. This enables tailored promotional campaigns and timely replenishment, preventing lost revenue from stockouts.

Maintaining the integrity of temperature-sensitive medications isn’t just a logistical challenge—it’s a strategic necessity for pharmacy distributors in Malaysia. The country’s tropical climate, with its relentless heat and humidity, creates a high-risk environment for drugs like vaccines, insulin, and biologics. Even minor temperature deviations during storage or transit can render these products ineffective, posing serious public health risks and regulatory consequences.

Modern cold chain logistics have evolved far beyond basic refrigerated trucks.

Today’s trusted solutions include:

✔ Real-time GPS-enabled sensors that track temperature fluctuations down to the minute

✔ Automated alert systems that notify managers instantly if thresholds are breached

✔ Cloud-based compliance dashboards that streamline NPRA audit documentation

A Kuala Lumpur-based distributor faced recurring losses due to spoiled vaccines until they implemented a proven monitoring system. The results were transformative:

Zero product spoilage after 12 months of use

24/7 temperature visibility, even for last-mile deliveries to rural clinics

Seamless audit compliance, reducing preparation time by 70%

For Malaysian pharma distributors, cold chain technology isn’t just about avoiding penalties—it’s about safeguarding patient trust. A single lapse can damage reputations built over decades.

Learn More : Pharmaceutical cold chain logistics: Best practices and challenges

Imagine a system that anticipates flu outbreaks before they happen or reroutes deliveries around monsoon floods automatically. That’s the power of AI-driven logistics in healthcare distribution. By analyzing years of sales data, weather patterns, and even social media trends, these systems predict demand spikes with uncanny accuracy.

A Penang-based distributor pharmacy uses machine learning to:

Adjust inventory levels before seasonal demand surges (e.g., Ramadan or back-to-school periods)

Optimize delivery routes in real-time, considering traffic jams and weather disruptions

Identify underperforming SKUs to prevent dead stock accumulation

The impact? 35% fewer stockouts during peak seasons and 18% lower fuel costs—proof that AI isn’t just futuristic jargon but an effective tool for everyday operations.

Perceived complexity (“Do we need data scientists to run this?”)

Upfront costs outweighing visible short-term ROI

Integration headaches with existing inventory software

Yet, as one Ipoh wholesaler discovered, starting small pays off. Their pilot AI program for predicting antibiotic demand now saves RM12,000 monthly in excess inventory costs.

Learn More : How AI is transforming pharmaceutical logistics

The road to digital transformation is littered with good intentions—and stalled projects. While large pharmacy wholesale distributors might have budgets for robotics and AI, smaller players face essential hurdles:

✔ Cost concerns: Warehouse automation systems can exceed RM500,000—a daunting figure for independents

✔ Skills gaps: Staff accustomed to manual processes may resist or struggle with new systems

✔ Legacy system inertia: Outdated software that can’t “talk” to modern platforms creates data silos

A Seremban-based distributor shelved their automation plans after realizing their 20-year-old inventory system couldn’t integrate with new tools. Their stopgap solution?

Started with barcode scanners to reduce picking errors

Added cloud-based temperature loggers for cold chain products

Gradually introduced AI demand forecasting for fast-moving items

Strategic partnerships matter. Collaborating with vendors who offer tailored training (in Bahasa Malaysia and English) can ease transitions. Some distributors leverage MIDA grants to offset 30-50% of digitalization costs—a often-overlooked opportunity.

The next decade will redefine healthcare logistics in ways that seem like science fiction today:

Emerging game-changers:

Blockchain trackers letting patients verify a drug’s journey from factory to pharmacy

Autonomous delivery drones reaching remote clinics in Sarawak within hours

Smart warehouses where robots handle 90% of picking and packing

But technology alone isn’t the answer—cultural readiness is. A Johor Bahru distributor learned this the hard way when staff ignored their new AI alerts, relying instead on “gut feeling” orders. Successful firms invest in:

Digital literacy programs for all employees, not just IT teams

Pilot testing with single product lines before full rollout

Regulatory foresight, anticipating how NPRA guidelines might evolve with tech advancements

One thing’s certain: distributors clinging to spreadsheets and landline orders won’t survive Malaysia’s digital-first healthcare revolution.

Learn More : How digital transformation is reshaping pharmaceutical distribution

The message is clear—pharmacy distributors who delay tech adoption risk becoming obsolete. Yet, transformation doesn’t require “boil the ocean” overhauls. Start with high-impact, low-complexity solutions:

First steps for Malaysian distributors:

Digitize temperature monitoring for cold chain products (fast ROI, minimal training)

Implement basic analytics to identify top 20% best-selling SKUs

Explore integrated platforms that unify ordering, inventory, and delivery tracking

For those ready to take the next step, PriooCare Malaysia offers expert guidance—from selecting the right tools to securing government incentives. Their tailored approach has helped distributors in Penang and Kuching cut costs by 22% while improving delivery reliability.

The future belongs to distributors who see technology not as an expense, but as the most reliable way to serve pharmacies, clinics, and ultimately—patients. The question isn’t if to adapt, but how soon.

📞 Professional Call-to-Action

Explore how PriooCare’s distribution solutions can future-proof your operations. Contact our team for a no-obligation consultation on integrating automation, AI, and compliance technologies tailored to Malaysia’s healthcare landscape.